5 reasons why CFD (Computational Fluid Dynamics) is so important for the development of automotive aerodynamics

In ye ole’ days, engineers used to rely solely on experience, and later on wind tunnels to develop the aerodynamic treats of their creations, most of the time doing a complicated process, which was expensive and time-consuming.

In ye ole’ days, engineers used to rely solely on experience, and later on wind tunnels to develop the aerodynamic treats of their creations, most of the time doing a complicated process, which was expensive and time-consuming.

As the information age came, ingenious people wondered if all of that processing power could be used to simulate what was going on in a wide range of situations. In the earliest days of computing, fluid dynamics stepped in and revolutionized the world of aerodynamic projects. So here are five reasons why this has happened.

1 It’s cheap (ish)

As CFD involves only electricity and enginner brain matter, it is wildly cheaper than conducting wind tunnel experiments, which requires making actual models of what is going to be tested. As a result, many teams and automakers tend to begin their studies on computed ambients in order to obtain a fairly consistent model to get to the wind tunnel. This leads us to the second point…

2 It gives much more flexibility to engineers.

Just like making a prototype is costly, adjusting a real model is something much more expensive to do rather than quickly changing your computer-generated model. Thus, engineers stand a much better chance to end up with a more refined end product, that will spare that lovely petrol you worked so hard to buy or to shred tenths of seconds on the race track

3 The final analysis can be much deeper than with experimental testing.

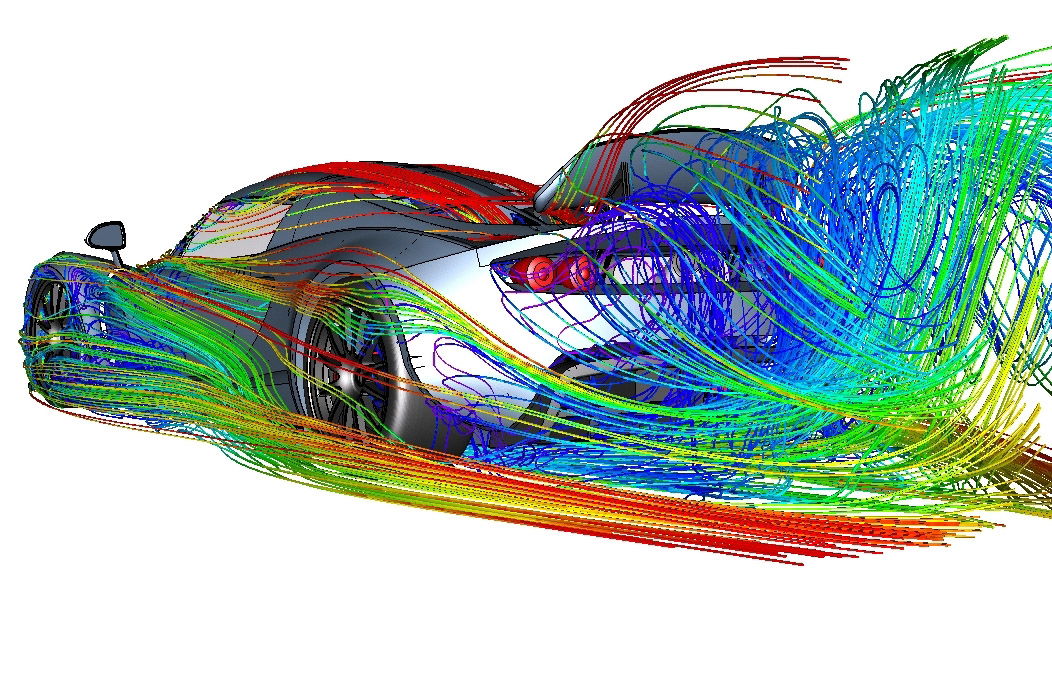

With CFD, you can analyse the force acting on the tiniest bit of your car, visualise all of the streamlines alongside with the respective airspeed on each point and also the whole pressure field around your object of study. Even on the best-instrumented wind tunnel in the world, you cannot get such data with such ease. Again, this will result in a finer project and a better product/track weapon.

4 The precision can be absurd

With numerical techniques being refined over the years, CFD has become a solid tool for projecting anything where aerodynamics and other fluids (liquids and gases) play a big role. Most of the time, wind tunnel testing is conducted in order to validate (i.e. to prove the CFD model is indeed correct) the results obtained with computer simulations.

5 It is not only useful for aerodynamics, but for other parts of the car too!

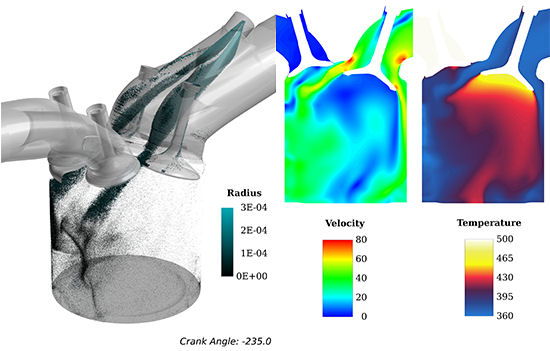

Most internal combustion engines from the last 10 to 15 years have been made with help of CFD. Basically anywhere you’ll see any type of fluid (gas or liquid) moving, I can assure you someone has used CFD to do it. Some other examples? Intercoolers, air-conditioning, brake cooling and the list goes on. Computer simulation is here to stay, and the results are everywhere.

What do you think? Leave your answer in the comment section! Hope you enjoyed!

Comments

Where can we apply for a job like this?

Totally agree!

As a matter of fact , we are taking part as a university in IV MotoStudent.

We have to use CFD analyses.

I’m studying internal flows on the intake manifold :D

I’m an aerospace engineer actually. I work with CFD and Computer Aided Design solutions on a day to day basis. From experience I can tell you that none of what we accomplish today in both the Aerospace and Automotive industry would be physically possible without CFD. This also applies to similar iterative software for structural analysis leading to the creation of things like carbon fiber tubs or aluminum space frames. If anyone has any questions on this topic feel free to ask!

Great info… Thanks for sharing

Great article! Would love to create a model of my car someday and try to put it through CFD, to see what improvements can be made to the aerodynamics.

Taking a Fluid Dynamics course next semester. This makes me look forward to it instead of dreading it now

I am studying computational engeeniring and I have done some cfd simulations. We had a model of a opel fastest car in 1927 (Opel Rak. 2). Car had wings and we did simulation of those in NX Siemens 9. I liked it. And btw great post.

I don’t know if this would be a point, but in real life, when you want to measure something, like airflow, I’d imagine that’s difficult to do without also interfering with the airflow. As you say, any CFD work has to be validated in a wind tunnel, but that isn’t a completely accurate environment either, right? And measuring airflow on a moving car, on the track would require sensors which could possibly interfere with the airflow I’d imagine. So would that make CFD better in terms of minimizing interference from sensors?

Sorry if it was poorly worded, but you answered my question. But I was asking about what you mentioned where the instrumentation needed on track can change the behaviour of the car, and whether that would be another advantage with CFD. But then I imagine CFD isn’t as accurate as a wind tunnel.

I appreciate the time you took to answer! Thanks!

And to add to what On the Apex said. There is always error in both wind tunnel testing and CFD. The allowable error all depends on what you’re making and how accurate it needs to be. In CFD, the more processing power you have the more accurate the model and the simulation can be. The issue companies run into is the cost of CFD, if they don’t own a supercomputer it can get rather expensive, and so can wind tunnel testing. If you’re making something like a fighter jet, take the F-22 raptor for example, your simulation must be extremely accurate to ensure the stability and control in the craft is at the exact level you want it to be. On the flip side, let’s say you’re studying the active spoiler on the F Type R, your simulation needs to get close enough to be within a few percent of the actual car, but it doesn’t require the same level of accuracy so money can be saved there. Neither CFD nor wind tunnel testing are perfect environments, they just give engineers a very accurate estimate on what will occur in a real world situation.

Pagination