Different Types Of Clutches And How They Work

Clutches form the bond between getting the energy from all that internal combustion in the engine through to the transmission and then finally out to the driven wheels. And with countless combinations of engine and transmission types scattered all over the automotive world, many different denominations of clutch exist to adhere to the job required. Whether they’re dealing with 90bhp or 900bhp, there’s a clutch out there that - once engaged - will be able to help transmit as much torque as possible through to any transmission.

Before we get started, click here for a basic overview of how a clutch works!

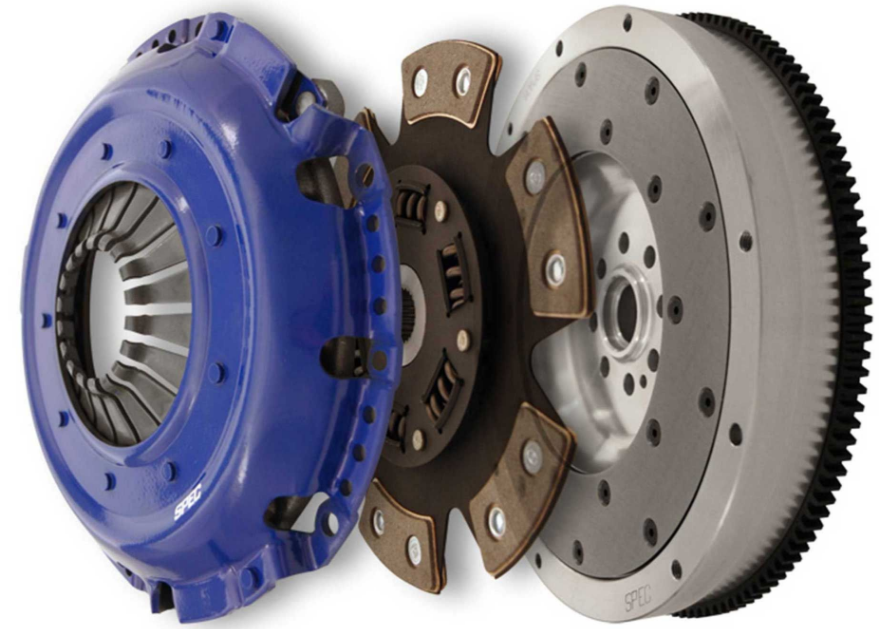

Basic friction clutch

Most cars use a form of friction clutch which has all the normal components that you have probably seen or heard of before. Operated hydraulically or by a cable, a friction clutch uses a pressure plate, a clutch plate (or clutch disk) and a release bearing to engage and disengage the flywheel and the transmission. Most cars will use a simple single-plate clutch, with only higher powered engines needed a multiplate clutch to engage the transmission properly.

When the clutch pedal is depressed, the release bearing applies a pressure to diaphragm springs on the pressure plate which releases a clamping pressure on the clutch plate and disengages the transmission from the flywheel.

As the gear change is made and the clutch is released, the release bearing is sent back from the pressure plate and the clutch plate is again clamped and driven by the pressure plate, allowing drive through to the transmission.

Wet and dry clutches

Wet clutches in general have multiple clutch plates (in cars) and have a supply of oil to lubricate and cool the components. They are used in high torque situations where friction levels would be high and therefore clutch temperatures would soar without some form of coolant. Any powertrain over 250lb ft of torque should really be employing a wet clutch to avoid excessive wear on the rest of the transmission through overheating.

Dry clutches on the other hand have no oil supply and are generally single-plate. This means they can be more efficient as lubrication can lead to a lack of friction between the plates in a wet clutch as well as producing parasitic losses from the drivetrain as a pump is needed to supply the lubricating oil. The small coefficient of friction in a wet system is therefore the reason for having multiple plates for effective clutch performance.

With multiple friction plates stacked on top of each other, obvious benefits are that the amount of friction generated within the clutch can be greatly amplified and therefore it can cope with much higher torque inputs. Used in many racing cars including Formula 1 and WRC, the amount of friction needed to stop the clutch slipping can be fitted into the same diameter as a single-plate clutch due to the neat stacking.

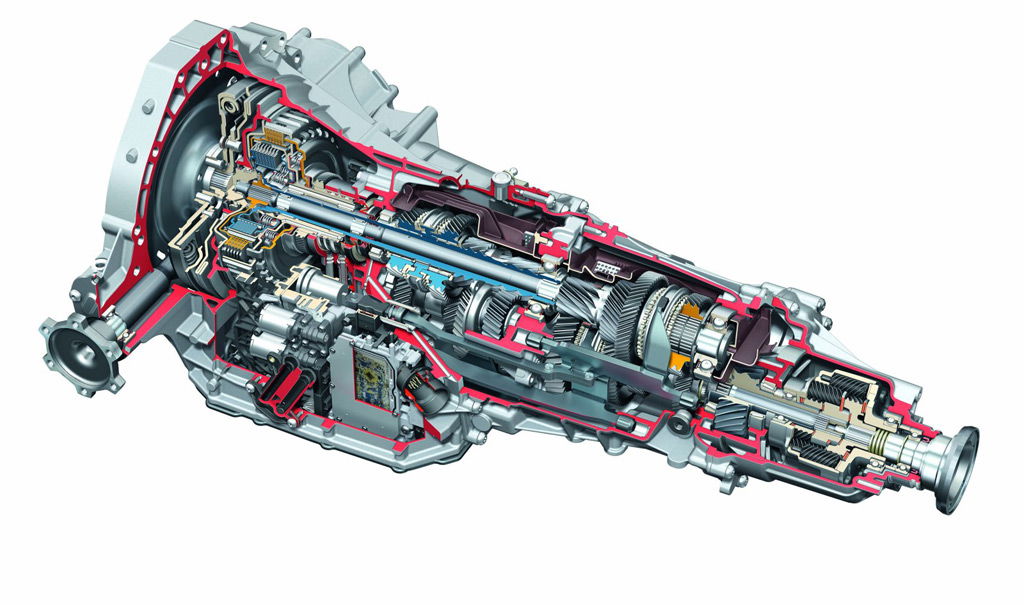

Dual-clutch systems

Dual-clutch transmissions now dominate the premium car market after their first general release through the VW Mk4 Golf R32. Using one large clutch for odd gears and a smaller clutch for even gears, this form of transmission is renowned for quick, smooth changes and is now found in every supercar worth its salt, as well as many hot hatches and saloons.

Used in automatic and semi-automatic setups, DCTs use two wet multiplate clutches which eradicate the need for a torque converter. The shifts are seamless due to the fact that the torque output to the driven wheels is not broken as it can be applied to one clutch while the other is disengaging, meaning no break in output.

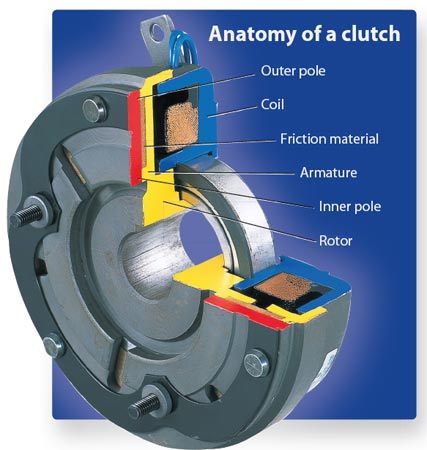

Electromagnetic and electrohydraulic clutches

Electromagnetic clutches can be used when mechanical sympathy and timing of clutch operation is generally disregarded, with the clutch being actuated by a simple button press on the gearstick or even a proximity sensor when your hand is near the gearstick. When the clutch is actuated remotely, a DC current passes through an electromagnet which produces a magnetic field. The armature is then attracted to a rotor, creating a frictional force to engage the engine and transmission.

Electromechanical clutches are prominent in the automotive industry, used in virtually every paddle-shift system. By pulling on a paddle, an electrical signal is sent to a computer which engages a servo to disengage the clutch hydraulically.

This negates the need for any form of clutch pedal and when combined with a DCT transmission can become the most efficient form of gear changing on the market. In general, these systems are used alongside more powerful powertrains and therefore use multiple plates within the clutch.

There are a few other clutch types out there, but most of them are either extinct or are only used in much smaller factions of the automotive sector. For example, centrifugal clutches are widespread in the moped and biking industry, using shoes (like on a drum brake) to engage and disengage the clutch. Dog clutches are also used in non-synchromeshed transmissions but necessitate double de-clutching and were brushed under the mat once gearboxes evolved.

If you’re looking to get more power from your engine through modifications, thinking about your clutch is a must. As Alex experienced when turbocharging his MX-5, once torque reaches a level too high for your clutch, the plates begin to slip as they can’t handle the forces channeled through them. In this scenario, a clutch upgrade is needed, and numerous aftermarket specialists manufacture performance clutches for this reason. Most of us will only ever really encounter a standard friction clutch on our travels, but there are plenty options out there if an increase in power is on the cards.

Comments

This was a very clutching post

A very engaging article! :D

This article was more gripping than a multiplate clutch

Dual-clutch transmissions <3

Great article, one question i have is that if the torque output is slightly abive 250 (around 300), will it be essential to have a wet clutch system or are there simply upgraded clutch disks to handle the extra torque?

What about the aventador?

Please stop making technical article when you don’t know a thing about the subject!

“Any powertrain over 250lb ft of torque should really be employing a wet clutch” … really ?

“Used in automatic and semi-automatic setups, DCTs use two wet multiplate clutches” Dual clutch are ONLY used in semi-automatic transmissions… and no, they aren’t always wet clutches.

“Electromechanical clutches are prominent in the automotive industry, used in virtually every paddle-shift system. By pulling on a paddle, an electrical signal is sent to a computer which engages a servo to disengage the clutch hydraulically.

This negates the need for any form of clutch pedal and when combined with a DCT transmission can become the most efficient form of gear changing on the market. In general, these systems are used alongside more powerful powertrains and therefore use multiple plates within the clutch.”

You are mixing everything… Clutch packs in a regular automatic and actuators in a DCT…

And the only place where an electromagnetic clutch is used on a car is the A/C compressor (or sometimes some other accessories driven by the engine), not in a transmission!

There’s no torque rating where wet clutches should be used at all, I’d bet a lot of cars with over 250lbft, the vast majority in fact, are dry clutches.

Wet clutches are generally a duty-cycle and/or wear reduction strategy. For things like bikes where a tiny compact clutch can expect to be slipped a lot in traffic with plenty of revs on to stop the motor stalling, or commercial load-lugging vehicles where longetivity is key.

Mind the downside to that is all the debris gets washed into the oil…

hi, I wanted to know about the difference between application of multi-plate clutch and racing clutch..

Can anyone help?

Really well explained.