Dry Sump Systems Explained And Why You Need One

The oil system is one of the most important features of any car and should never be underestimated or taken for granted. With the sheer volume of moving parts which in turn create a whole tonne of friction, it’s essential that all of the necessary parts stay lubricated and free moving, thus keeping the engine operating at a smooth and efficient level.

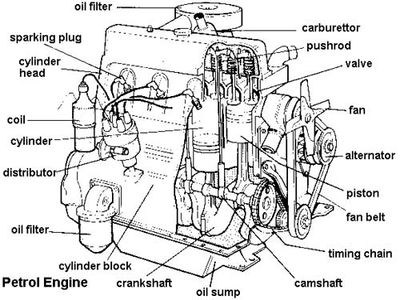

When it comes to liquids within a mechanical system like an engine, there are always a couple of general features that resonate throughout. Firstly, there has to be some form of reservoir, somewhere for the bulk of the fluid to sit before being sent away for lubricating duties. The propulsion of the fluid is then performed by a pump which propels the fluid from the storage unit to wherever it needs to lubricate. It gets there by the use of channels that are built in to route the lubricant throughout the engine to the specific areas needing a reduction in friction.

In a traditional oil system, the reservoir/storage unit is called the sump. This is a chamber that lies at the base of the engine underneath the crankshaft, otherwise known as the oil pan. This produces a simple solution for oil storage due to the fact that gravity will always pull the liquid down into the sump from where it can sit and then be redistributed.

Unfortunately, there are some inherent problems that occur from using this method, the first of which being oil starvation. As a car is cornering, the lateral g-force acting on the car will force the oil to lean to one side, sloshing in the opposite direction to travel. If cornering is therefore frequent or constant, the oil continually sloshes to an area of the sump where the oil pick-up cannot access it, meaning a lack of oil reaching the pump so the engine does not receive the amount of oil required to effectively lubricate itself.

The presence of a sump also means that the engine block itself is a very tall, heavy lump of metal that only detracts from the car’s performance due to its placement causing a high centre of gravity.

One way around this problem is a dry sump system.

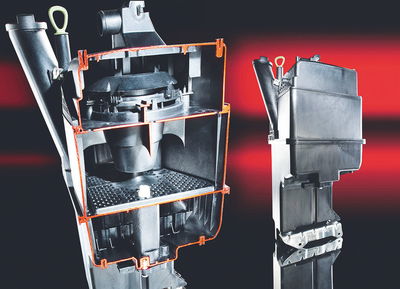

A dry sump is created by removing the sump from the bottom of the engine block and instead placing an oil reservoir elsewhere in the engine bay. Using some form of container for storage, the oil is then pumped internally to the engine from an external position. This is accomplished using an extensive route of silicone and metal piping that travels from the reservoir to wherever the lubrication is needed.

The external reservoir means that oil starvation is a thing of the past (as long as the pump is fully reliable) so the life span of an engine – especially in motorsport – is greatly increased. The specific routing of the oil by the oil lines means that you can also be very specific with where the lubricant is being applied. A small sump still exists to collect the oil that makes its way to the base of the engine but it is very shallow and the excess oil is quickly scavenged back to the external reservoir.

In terms of the engine block itself, the lack of a large sump on the base of the block means that the engine can be mounted much lower in the car’s engine bay. This puts the dominating weight of an engine block nice and low within the car’s chassis, thus improving the centre of gravity placement, weight distribution and the general dynamic abilities of the car in question. Some manufacturers have gone even further and added active-engine mounts to the block which further manages the engine’s bulk to help performance.

Another simpler method of avoiding oil starvation is baffling. By welding in slats of metal within the sump or onto a metallic sump gasket, the oil will slosh into these small barriers, keeping a much larger amount of liquid within the catchment area for the oil pick-up. Although this is not a fool-proof method against starvation, it is a much cheaper solution for most manufacturers instead of a full dry sump system which can require a whole load of reconfiguration within the engine bay.

Much like a cooling system, a true petrolhead really shouldn’t neglect the vital life supply for their engine that is the oil supply. An engine starved of oil gets very hot very quickly, along with wear on the moving parts dramatically increasing, potentially leading to catastrophic engine failure. So if you’re in the mood for a slightly convoluted but rewarding modification that you can reap the rewards from dynamically, a dry sump isn’t a bad shout.

Comments

Car Throttle’s very own Engineering Explained. Awesome job as usual 👍

What would a wet-to-dry sump conversion job entail? Let’s assume we leave the engine at the same height in the bay.

Would a new custom oil pan need to be manufactured? What would you do with the stock oil pump? How big of an external reservoir would you use? Finally, at which point in the system would you put the oil cooler and oil filter? Before the reservoir or after?

My 2 cents of thoughts.

Both a wet and a dry sump use an oil pan, but in the dry case you need to connect the oil pan to the reservoir. So i would make a new pan, which is half the volume and has an outlet to which i can connect a pipe.

The reservoir needs to hold the same volume of oil as the stock, if you’re running a stock engine. Or if you have oil needing mods, i would say the same volume of oil before going to dry sump.

The filter, i would say before the pump, just like a gas filter. The pump creates pressure which sucks the oil from the reservoir it goes trough the filter and all the junk is trapped there.

The oil cooler. IMO it should be before the oil enters the reservoir so you will keep a cool reservoir, but need to move the oil filter before the cooler so you don’t clog it, (please someone correct me if i’m mistaken on how an oil cooler works).

Dry sump kits are available for almost every engine out there.. You would want new oil pan, oil cooler (it works very much like a radiator),reservoir, electronic pump (some people use external oil pumps powered by cam belt that feed oil individually at each cylinder, these are very similar to mechanical injection pumps, with a tiny camshaft in it that circulates oil at the very best moment it is needed during stroke for reason that are way beyond my comprehension) you would also need a reservoir and a hell lot of high pressure piping! New filters etc.. Those kits are veeery expensive! But a reliable one is worth every cent.. It not only provides you with assurance that your oil will be at the right place, at the right time, but it also eliminates the defects of your traditional oil pump.. The oil circulates much more freely and smoothly, and that leads to a much cooler,smoother,cleaner,quieter engine. Plus you have a seperate reservoir to check much more easily the quality,viscosity and color of your oil.. Which on a mechanical level, will provide you information about your internals and the efficiency of your system, that can in no way be compared to traditional oil feeding system..

Pretty sure that’s an air filter on top of the first diagram.

Old cars used oil baths. Look it up. The idea is actually very effective depending on the application. If your intothat sort of thing.

Forgive me if I sound really stupid but is that why some cars dont have a dipstick at the engine bay (my dad’s old bmw had an electronic measurement system)

Not necessarily no, a dry sump will still have a dipstick… BMW use this trick to make “diy” mechanics more difficult

“sparking plug”, “oil filter” on air filter, “carburettor” this diagram is a troll!

Well no, as older cars used oil bath air cleaners

No, it’s just quite old

Nicely explained, but why use pushrod engine for demonstration? In more than half of the world they are long forgotten..

Can I get one for my 87 IROC?

I have a feeling it costs a lot to do on a regular car

*Enginnering Explained leaves CT

Prettuysure that diagram is of a A series engine ….

Pagination