Engineering Explained: 6 Times Car Makers Had You Fooled

It’s easy to judge a car based on what marketing has taught us over the years, but don’t be decieved by these six fallacies:

- Koenigsegg Makes The Most Impressive Engines

- AWD Quattro Is Better Than Subaru Symmetrical AWD

- Steel Is Better Than Aluminum

- SOHC Is Outdated And Pointless

- Pushrod Can’t Compete With DOHC

- High Compression Ratio = More Power

1. Koenigsegg Makes The Most Impressive Engines

The Koenigsegg One:1 pumps out a staggering 268hp/litre out of a 5.0-litre V8 (1341hp). Hence, Koenigsegg makes the most impressive engine in the world, right? It’s really not that simple. Specific output (horsepower per litre) often comes down to just how much air you force into an engine. Increase the boost, and the specific output goes up. The engine may not last as long, but it sounds more impressive on paper. The stat is much more meaningful if you tweak the data to compare apples to apples. Take the Ferrari 458 Speciale for example. It produces 595hp from of a 4.5-litre V8, which equates to 132hp/litre. The Koenigsegg V8 makes double the power per litre, but with 26 pounds of boost.

The amount of air an engine can pump into its cylinders relative to its size is known as volumetric efficiency. A really well engineered naturally-aspirated engine can hit around 100 per cent volumetric efficiency (or above, with enough air velocity), though with forced induction this number can be much higher. With 26.1 PSI of boost, the Koenigsegg’s volumetric efficiency is about 277 per cent. Effectively, it means the engine is more like a 13.9-litre naturally-aspirated engine, and in such configuration produces 97hp/litre. The figure is still impressive, but in comparison to the Ferrari, it’s significantly lower. Even correcting for the low compression ratio versus Ferrari’s absurd 14:1, the Ferrari still makes over 20hp per litre more. It’s also worth noting that as you crank up the boost, cylinder pressures and temperatures increase, and this affects longevity. Having low horsepower per litre engines can be beneficial as the internal stresses remain lower, often leading to a very reliable engine.

2. “Audi Quattro Is Better Than Subaru Symmetrical AWD”

The point here isn’t to claim that Audi, Subaru, or any other manufacturer for that matter make the best AWD system. Instead, it’s that the statement “Quattro is better than Symmetrical” holds almost no meaning. The terms Quattro, Symmetrical, S-AWC, SH-AWD, X-drive, etc. are all just marketing terms to state that the car can drive all four wheels. As you might assume, the Audi R8 doesn’t run the same AWD technology as the Audi A4. Even higher end Subaru offerings like the WRX and STI have drastically different AWD setups, though both are marketed as “Symmetrical AWD.” While the STI boasts front and rear limited-slip diffs, the WRX makes do with open front and rear axles. Ultimately, cars need to be analysed individually in order to determine which AWD solution will be best for a certain condition.

3. Steel vs Aluminum Body

Chevrolet has put out extensive advertising campaigns to discredit Ford’s work with the aluminium bodied F-150. Along with insinuating the idea that trucks need not care about efficiency and weight, they state boldly at the end of their Aluminum Man ad that “some things shouldn’t be made of aluminium.” Chevy engineers probably hung their heads in shame after watching the ads. After all, nearly all engines these days are made with aluminum blocks and heads, and it’s been reported that Chevrolet will be increasing the use of aluminium in future trucks. Of course they will. Aluminium is strong, light in weight, and has great corrosion properties. But do you think they’ll advertise the new truck as unsafe at launch? Unlikely. Repair costs may be slightly higher, however since insurance costs remain comparable it’s a non-issue for many of consumers (especially considering how common it is in the States to buy a truck for no utilitarian purposes). The weight reduction also helps save on fuel costs.

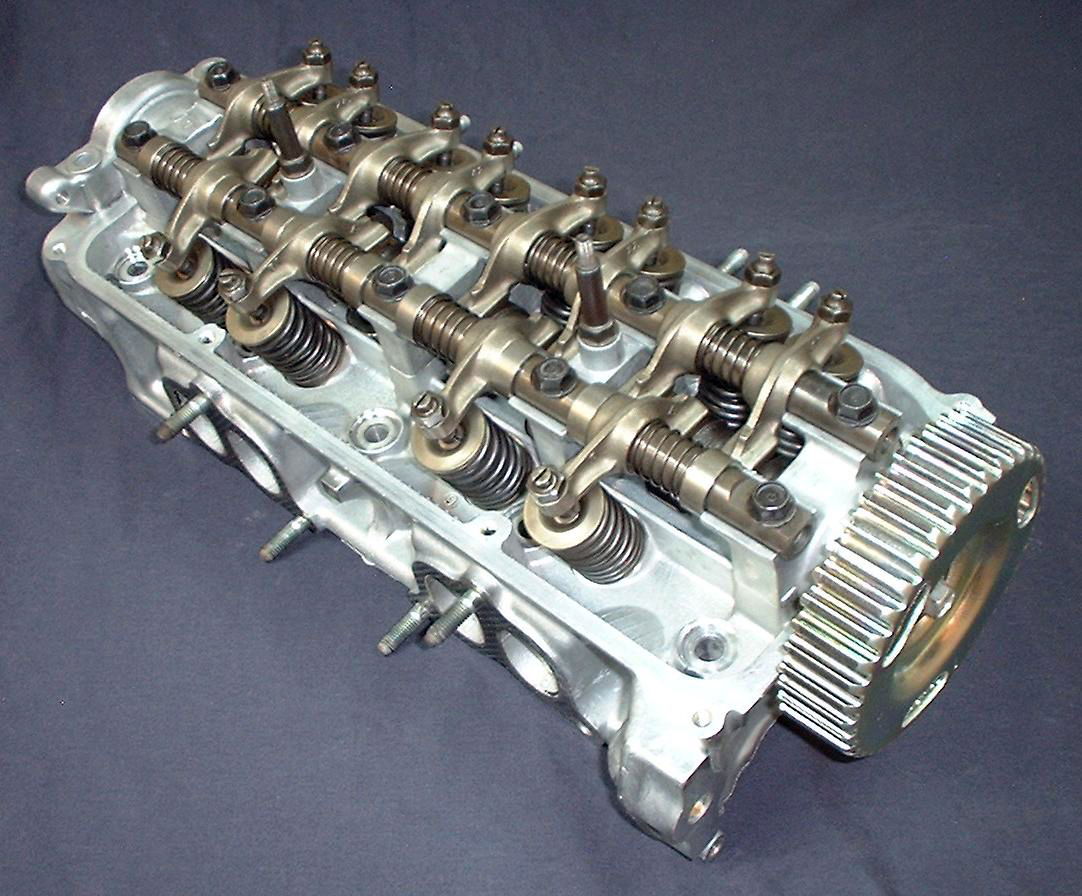

4. SOHC Is Outdated And Pointless

DOHC is indeed an incredible technology that allows for variable cam phasing for both intake and exhaust valves, but the idea of using single overhead cams in the modern era shouldn’t instantly be dismissed. Not every car needs insanely efficient airflow at high RPM, considering that the majority of car owners (the A to B folks) don’t even know how much power is under the hood, nor care. For your run-of-the-mill sedan or SUV, using SOHC is a way to save cost and complexity where DOHC isn’t a necessity. You can still use four valves per cylinder, and you can still vary the intake valve timing. To name a few, Honda, Chrysler, and Mitsubishi all continue to offer SOHC engines.

Additionally, there are applications where SOHC can directly compete with DOHC, even from a performance standpoint. While technically classified as SOHC, Fiat’s Multi-Air Technology is essentially just as capable as a dual cam valve-train. The exhaust has a traditional camshaft, however the intake valves are actuated hydraulically with adjustable valve lift and timing. Simply reading that a car’s engine has a single overhead cam isn’t nearly enough information to determine if the design is efficient or powerful.

5. Pushrod Can’t Compete With DOHC

While it’s true that four valves per cylinder will allow for more airflow (keeping valve lift constant), that’s not to say that there aren’t benefits to a pushrod design. By placing the camshaft within the V of the block, the cylinder heads can be shorter and the design is much more compact, allowing for better placement and a lower centre of mass. Having a smaller engine also frees up room for suspension design, or a narrower body if desired. Of course, cost and complexity will always play a role, adding reasons as to why Chevrolet continues use of OHV engines.

Admittedly, DOHC does have distinct advantages when it comes to high-revving engines. Smaller valves have less mass and are less likely to cause valve float, an issue where valves don’t follow the exact curve of the camshaft as a result of the reciprocating movement and the valve springs not keeping up with the demand. The solution isn’t quite as simple as it sounds, as adding stiffer valve springs reduces efficiency and increases stress on the valvetrain. As a result, DOHC engines have an inherent advantage to rev higher as the valves used are much lower in mass and less likely to float.

6. Higher Compression Ratio = More Power

This is another case of not fully understanding an engine but judging its performance based on compression ratio. The Mazda6 features a 2.5-litre engine with a compression ratio of 13:1 that produces 184hp. The Acura ILX pumps out 201hp from a 2.4-litre engine with a 11.6:1 CR, giving it an additional 10hp/litre even though the compression ratio is lower. The lacking information is that these engines run on completely different cycles. Unlike the traditional Honda engine, the Mazda leaves the intake valves open during a portion of the compression stroke, forcing air and fuel back into the intake manifold, and reducing the effective compression ratio. As a result of having a larger expansion ratio than compression ratio (the combustion gases have more space to expand than they were compressed), the specific output plummets, but the efficiency increases. This is how Mazda has managed a 40mpg highway sedan without a small turbo engine. The tech is also used on demand in the Lexus RC-F, switching to the Atkinson cycle when power demand is low.

Comments

Geez, it’s almost as if those stupid Americans have some advantages to their low HP/L pushrod engines. Who would have thought such a thing?”

“ the WRX makes do with open front and rear axles” This is false. I don’t know a single Subi Turbo without a rear LSD (visco).

I don’t agree with your point on the Koenigsegg.

You’re actually comparing a billion dollar company (Ferrari) to a small independent manufacturer (Koenigsegg).

“The figure is still impressive, but in comparison to the Ferrari, it’s significantly lower.”

Ferrari has more staff, more financial muscle, been an established manufacturer for much longer than Koenigsegg and have a far more longer racing history than Koenigsegg. So to have a small manufacturer with tight resources as Koenigsegg or SSC and Hennessey for that matter is impressive - and on top of that are being able to blow Veyron out of the water (backed with VW money).

Am i the only one around here who instantly noticed that one of the wheel nuts on the Lexus RC F was diffrent (pause at 1:12 to see)

Good article as always :)

Cool write up! I have something to say about the aluminum stuff though. Aluminum bodied cars have been around for a while, so its a pretty proven material for car building. What Ford is not mentioning is that nobody wants to repair the new F-150s due to insane demands/regulations by Ford. We had a Ford rep come out to our shop and tell us that we needed a separate “clean room” and about $50k in additional equipment just to work on their trucks. Apparently the new aluminum is more sensitive (something in the material structure) to steel contamination.

So if you end up wrecking a new F150, good luck finding a shop that will take it! Dealerships don’t even want to work on them!

I wasn’t aware that Mazda used Atkinson/Miller cycle. I thought they were “only” using their high compression together with a very lean mixture.

www.thetruthaboutcars.com/2014/02/gm-to-produce-aluminum-body-pickups-s… Just leaving this here for Chevrolet anti-aluminum freaks.

I feel bad for GM engineers.

Here they are developing amazing cars like the Volt (which if you ask most hybrid enthusiasts is better than a Prius in almost every aspect), and the C7 Corvette. Then you have the marketing department makes the whole company look like idiots. Sure, the corporate side is mentally deficient, but the engineers are some of the best in the world.

And besides, they make LS engines out of aluminum. I wonder how GM engineers wanted to punch the marketing people after that commercial.

Who the hell thinks steel is better than aluminum? Must be America…

Pagination