The Ins And Outs Of Engine Braking

The art of engine braking can either be a help or a hindrance when driving, exploiting the suck, bang and blow of internal combustion in an inverse form. Experienced when acceleration has stopped and at 0% throttle, engine braking can be used to slow a car down as much as possible in tandem with the brakes. Engine braking can make coasting while off the throttle slightly frustrating as it saps your road speed at a rate that needs further throttle input down the road. But it does have its uses, so let’s take a look at how engine braking occurs and how it works in petrol and diesel engines.

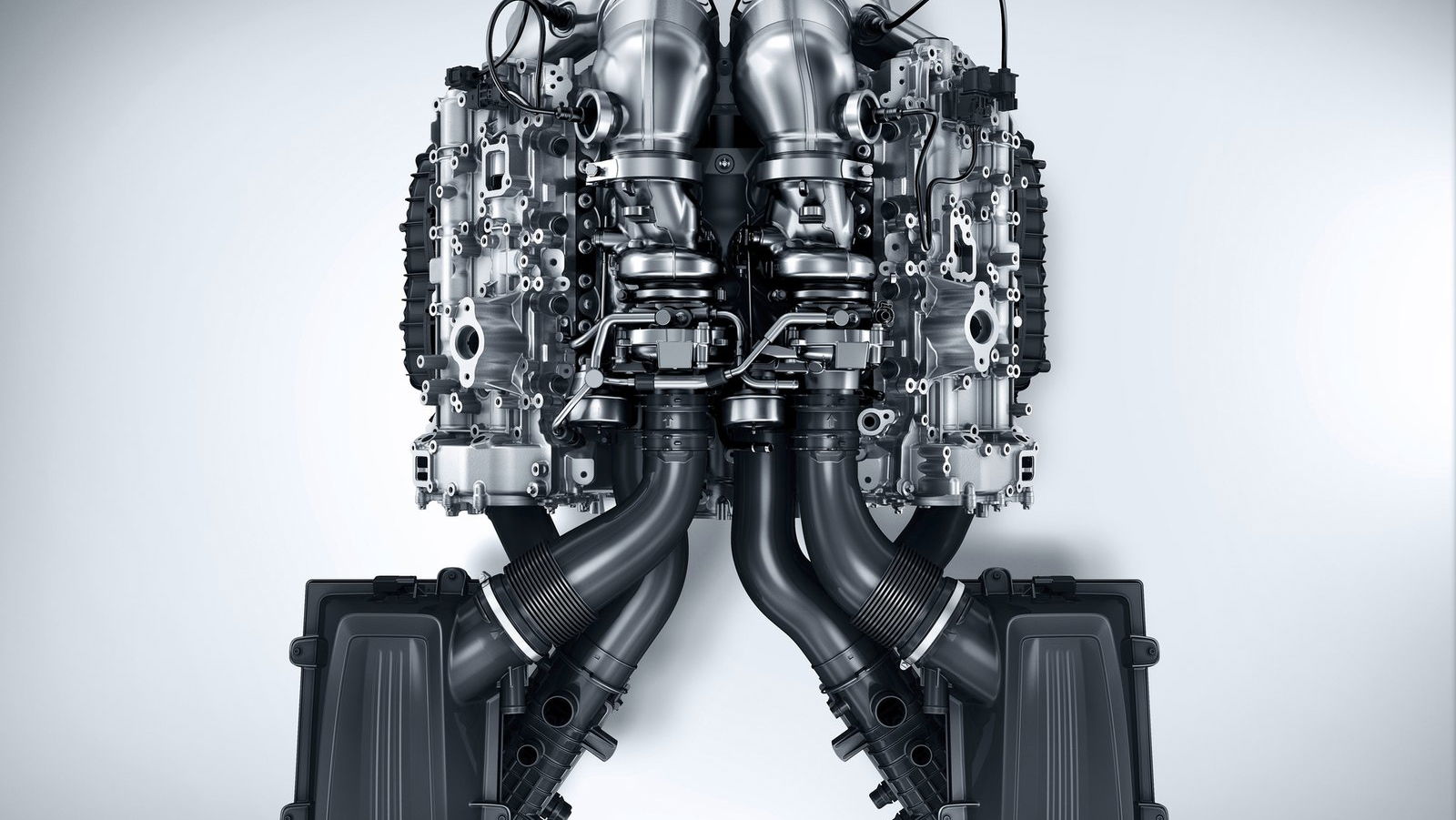

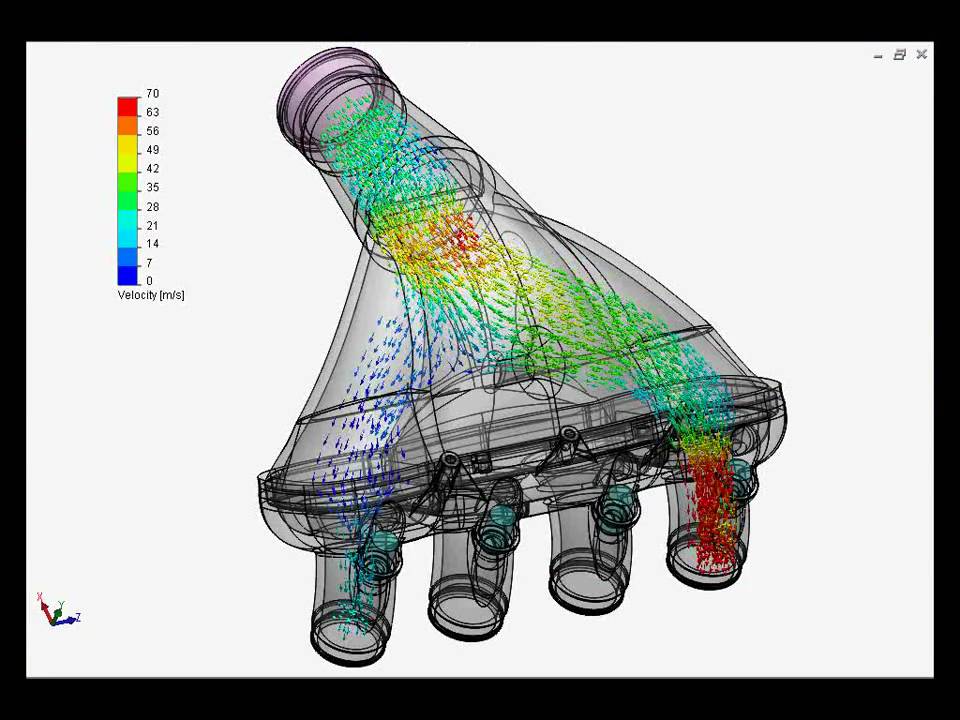

In its simplest form, engine braking occurs in a petrol engine when the throttle is released. When the throttle pedal is actuated, a butterfly valves opens at the engine’s intake, allowing air to enter the intake manifold to be mixed with fuel for combustion. So when the throttle is released, this butterfly valve shuts, allowing only a very small amount of air through to the engine.

This sudden closing of the airway forms a vacuum within the intake manifold which produces an opposing force to the pistons reciprocating within the engine. Imagine placing your finger over the end of a football pump and then trying to move the plunger upwards - a large opposing force formed by a vacuum within the cylinder will mean that the pumping piston won’t shift much at all.

The effort that the pistons have to exert to oppose the manifold vacuum saps energy from their reciprocation, forcing them to slow down and thus rotating the crankshaft slower, reducing road speed. This braking is therefore emphasised when engine speed is high as the large amount of air previously entering the cylinders is suddenly shut off, creating the vacuum that opposes a higher rotational force from the cylinders.

On top of the vacuum element, a minimal amount of engine braking is also achieved by friction between the moving parts of the engine. Although the oil system provides a more than suitable amount of lubrication to make sure the moving components don’t end up welding themselves together due to heat, there is natural friction between every moving piece of the engine as they interact with each other. This friction has a negative influence on the positive energy of the moving engine, thus stripping rotational energy from the crankshaft and ‘braking’ the engine.

Diesel engine braking

Unfortunately, diesel engines don’t have a throttle valve, so instead they use an exhaust valve that closes during the exhaust stroke of the engine cycle. Back pressure is then created which fights back against the motion of the pistons, slowing them down.

Another method used within diesel engines in through something called a jake brake; this is a device that uses a rocker arm to open the exhaust valve at the top of the compression stroke which allows a small amount of air to disappear off down the exhaust manifold instead of being fully compressed and then ignited. This results in a reduction in volumetric efficiency of the engine and therefore a decrease in power. Despite these two methods, diesel engines are much more efficient at coasting down the road off throttle due to the lack of reverse force that acts against the pistons in comparison to the powerful vacuum created within a petrol engine.

Engine braking has its real world advantages, one of those being on-road safety. That extra braking force will always help a car to slow down quicker and - if used regularly on purpose - it shows that the driver is aware of their surroundings and is in-tune with the capabilities and behaviour of their car. Your brake pads and discs will also thank you in the long run, as they have to scrub off less speed than if the clutch is disengaged and all stopping force is isolated to your brakes.

Another scenario where it has its advantages is when the ground is covered in snow. Instead of applying any sudden braking which can cause a sudden loss in friction between the tyres and the road, engine braking can be used to provide a much smoother reduction in speed.

Engine braking can resemble an art form if you are fully aware of the road ahead and can be implemented into daily driving with a bit of concentration and good judgement. Although to some extent it shows that the internal combustion engine is inherently working against itself, it’s good to know that your powerplant has a potential helping hand to give you if needs be. And to be honest, if you have a fairly meaty exhaust system, there’s nothing better than cutting off that air supply to the engine with a simple lift off the throttle, letting the revs slowly tick down in diminuendo of crackles and pops.

Comments

Maybe someone can answer me here : I always wondered if using engine braking for a long time can hurt your engine ?

Like a big montain road where you don’t touch the throttle for like 15min (or 30min), mid reving to have a good engin break, could this be bad ?

amazing

http://manfaatjellygamatgoldg.com

Just remember too flash your break lights too warn others when loosing a lot of speed ( no brake lights and big décélération is just dangerous )

When passing my motorbike test we were taught to flash our brake lights by gently touching the brakes two to three times to signal to other drivers our loss of speed ( motorcycles are light and engine break really well, and can easily surprise you. )

Unfortunately the closed throttle theory as the “cause” of engine braking disobeys a fundamental law of nature/physics: the law of conservation of energy.

On a long descent if we just used the brakes, they get very hot as we are converting gravitational potential energy(GPE) into friction/heat energy. If instead we use engine braking to maintain a steady speed during the descent the GPE still has to be dissappated. If it was any type of throttle restriction causing the energy less we would see red hot inlet manifolds or throttle plates in the same way we would see red hot brakes if we didn’t use engine braking, the theory falls over right there.

Where does the energy go, from the engine compressing air and transferring that heat to the engine block and out the exhaust. No, the energy used in compression is not 100% returned in the power stroke, the internal combustion energy is very inefficient

Also worthy of mentioning, a vacuum at best only applies 15psi of resistance(atmospheric pressure) to the pistons on the intake stroke, but as you all know, on the compression stroke, we can have from 100-200psi depending on rpm and cam profile……..that is where the braking effect comes from.

try WOT when engine braking with the ignition switched off(a direct wire throttle would be needed), it will actually cause a small increase in engine braking(reason as to why we test for engine compression at WOT), if the vacuum theory were correct the braking would disappear when this occurs, it doesn’t……..

In fact as I understand it the ecu on modern cars not only cuts the fuel when engine braking but sets the throttle to wide open when the rpm are above a threshold.

Pagination