Tig and Mig Welding-The basics and uses in today's car culture. #blogpost

In modern day car culture everybody has their dreams of owning a project car. Whether it’s an Ls swapped Fb Rx7, or a twin turbo Bentley. You will definitely come to a point were you have to join two pieces metal together. Welding has great roots in modern day society.

In modern day car culture everybody has their dreams of owning a project car. Whether it’s an Ls swapped Fb Rx7, or a twin turbo Bentley. You will definitely come to a point were you have to join two pieces metal together. Welding has great roots in modern day society. It is the thing that built our skyscrapers, our trains, our massive cargo ships and of course our cars. So what do you do? You know nothing about “welding”, and have no clue were to start. Of course you could pay somebody, but what is the fun in that? Lets get going shall we?

Lets start with Mig. Now what is Mig you may ask? Well, Mig is the abbreviation for metal inert gas, which is a form of welding that requires lot’s of electricity and a constant flowing steel wire. Mig is a very common and quite easy form of welding once you get the hang of it. This form of welding is what’s primarily used to make roll cages for example due to its fantastic results with steel piping. It is very versatile and can be used to join two pieces of steel together almost seamlessly, and only steel. One drawback of Mig welding is the issue with welding aluminum, you can’t do it. At least I don’t know of one which can. Must have aluminum wire hmm…Anyway!

On to Tig. Now Tig is the abbreviation for tungsten inert gas welding. It is much more advanced due to its ability to work with no constant flow of steel wire, and also the ability to weld aluminum with different forms of tungsten tips. I’ll talk about that later. Tig is a very complicated thing to explain, you will just get the basics. This form of welding is MORE versatile than Mig, and also much harder to learn. Tig requires very good hand eye coordination and a steady foot to operate gas flow. For some jobs Tig requires filler rods which have the same purpose as the steel wire in a Mig welder, just to add material and also strength. Tig is commonly used to weld custom exhausts.

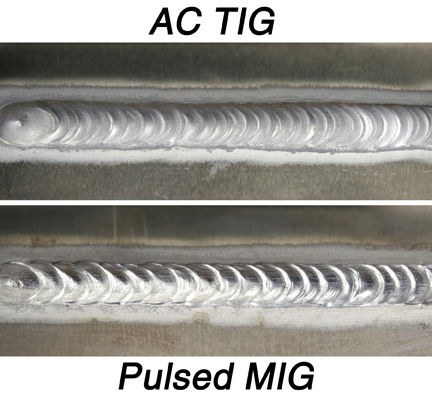

Now you know the basic differences, and hopefully how they kind of work. Both have their pro’s and con’s. With Mig you can only weld steel, Tig you can weld multiple kinds of metal. Mig is easier, Tig is much harder. Both require a clean surface and good ground to work properly. Tig is better for very small precise work, yet with Mig you can weld a whole building together. As you have seen before Tig is very pretty in the hands of a professional #weldporn yet with Mig you can practically drop a bead of birdpoop and it will still hold steel together “sort of”. Both of them can do basically everything you will ever need when it comes to building a project car. You can drop ten grand on any kind of welder or get one used for a few hundred dollars/euros and teach yourself in that creepy shed of yours out back.

Safety should always be considered when welding. A proper mask for the kind of welding you are doing and clothes. Welding produces light that is much brighter than the sun. You can burn your eyes with Tig and Mig very easily if you are not paying attention. Trust me, it flipping hurts.

Alright, so concluding I touched on the basic pros and cons of Tig and also Mig welding. The basics on how they work. What they can be used for, and also safety. I have about 4 years of Mig and Tig welding under my belt, trust me I could of made this post much more complicated. If you are just starting out, I would suggest Mig. If you are a brave individual, do some more reading and buy a Tig welder, they are better machines and can handle a wider array of work, for a bigger price. Who needs money anyway when you can have a Lamborghini V10 swapped drift Miata?

Comments

Love this. Great write up

Great post, I is learned lots! I’m going to bookmark this…I might need it soon!

Lovely post, I don’t really know much about welding so this was great. I’d love to learn to weld just don’t know where haha

Most economic solution is to go to a workshop and ask them to so it. Fact is that not everyone can do proper welding … even after lessons.

You can use a pulse MIG welder on aluminum.

Coming from a fellow welder this is a great post!

I’ve done both processes and TIG is very difficult but I love the challenge to get it perfect. With MIG you can weld with one hand behind your back and still get a good weld!

What a load of rubbish, you even have a picture of pulse MIG welded aluminium! You say MIG welding is easiest but you will see more shit MIG welds than any other, and done badly they will fail! Most modern cars are made of high strength boron steels and you can not MIG weld those, and if you do you will die as a result! You have to MIG braze the high strength steels! Please talk to an expert if you intend taking up welding and not rely on this very basic and simplistic nonsense!

Roll cages by the way should be MIG welded using chrome moly (1Cr Mo) wire to match the strength of the cold drawn steel tube you should be using. Please talk to an expert before welding any thing where an error could be fatal!

You can weld aluminum with a mig as long as you have a spool gun, because its such a soft metal it always ends up getting tangled if you just use the normal rollers

TIG is hard . Please some of us know how to arc weld, knowing if it worked or not isn’t easy with that stuff, its even harder if your using a coat hanger and not arc welding sticks.

Pagination