What Is Cylinder Head Porting, And How Does It Increase Horsepower?

There are countless ways to modify a car for more power, but they all come down to the same common factors: getting more air and fuel into the cylinders, combusting it efficiently and exhausting it as quickly and smoothly as possible. And although many petrolheads are obsessed with forced induction, cylinder head porting is a much less drastic but worthwhile modification that could bring a few more horses to the stable.

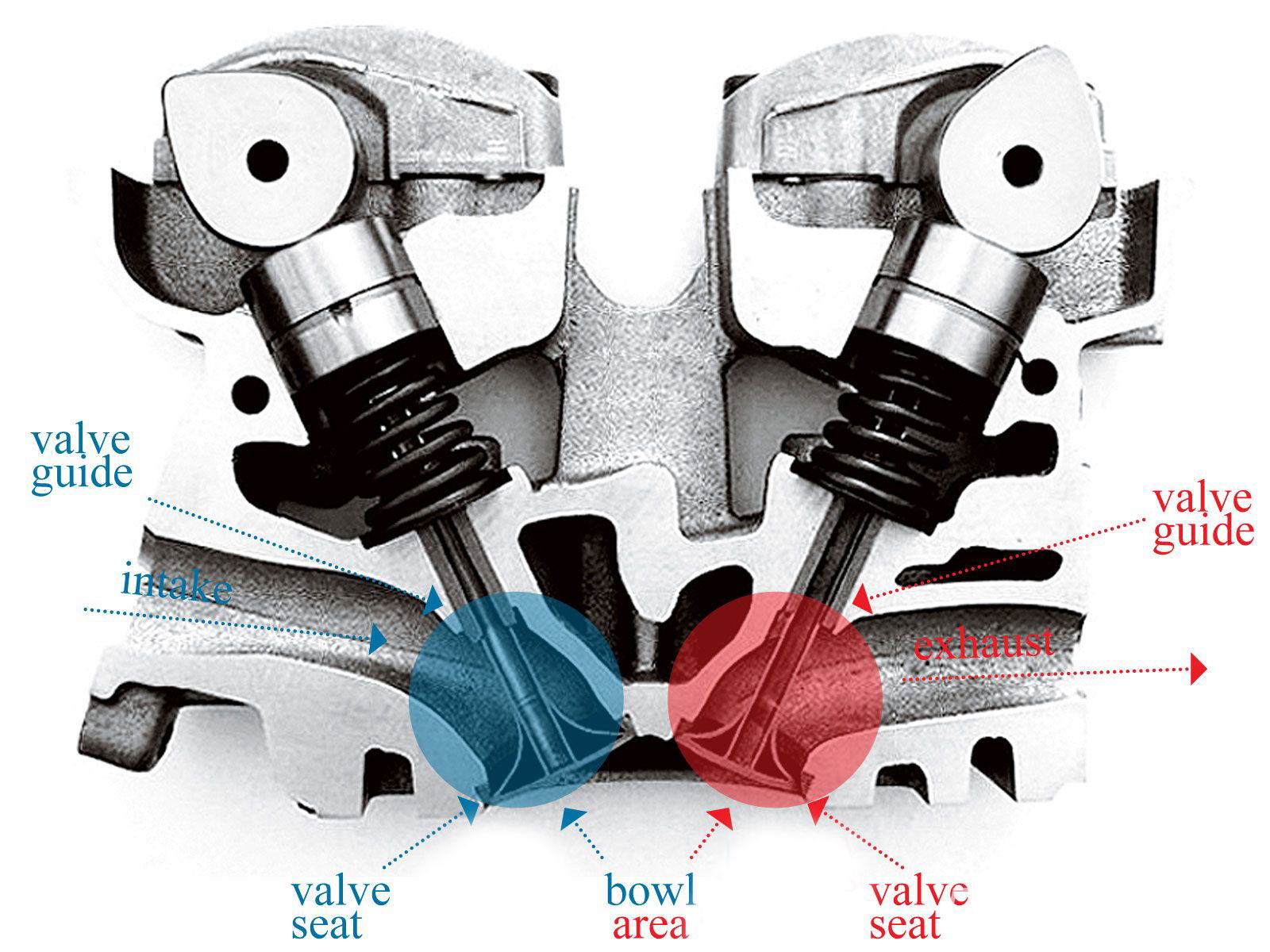

Cylinder heads are manufactured using a casting process, with cast iron or aluminium alloy being poured into a template to solidify. During this process, cast flash can occur, which is a defect caused by the metal leaking from joins in the cast and the contact between the base of the mould and the material when in a molten state. Once the base material of the head is manufactured, CNC machining is then used to mill out the valve seats and any other small chamfers and cuts needed to complete the cylinder head design.

What this all leads to is a fairly rough cylinder head, affecting the fluid flow as it makes its way through the side of the cylinder head and into the cylinders via the valve throat. For the most efficient fluid flow and maximum performance, the cylinder head can be machined to reduce the amount of small restrictions and rough patches that could hinder the flow into each respective cylinder. Reducing the turbulence of the fluid flow will produce a smoother intake and exhausting of the system, producing a power increase.

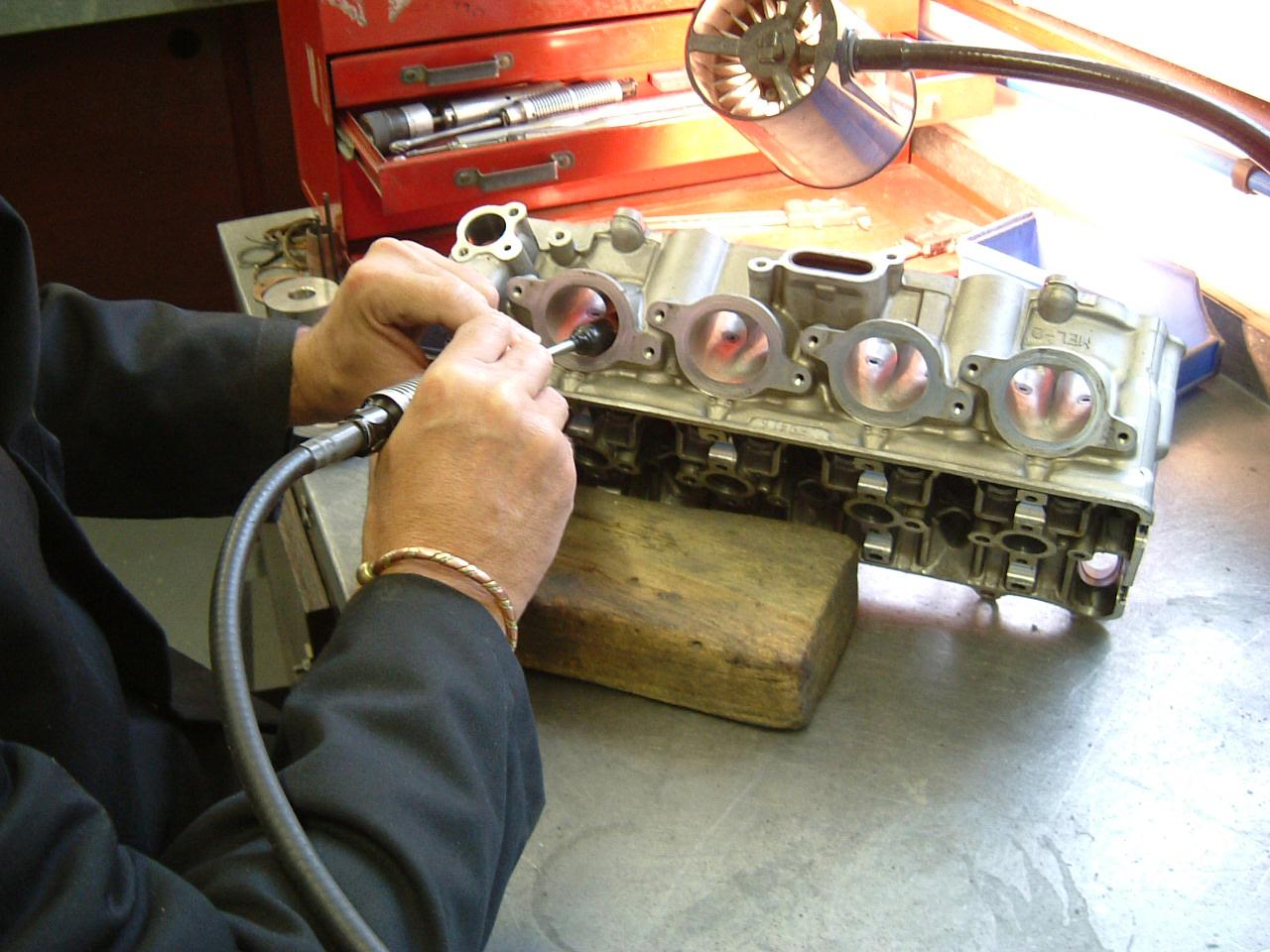

Basic head porting can be completed using a small handheld drill with tapered grinder drill bits, essentially acting as motorised sandpaper. For heavier-duty jobs like port matching, you’ll need a die grinder and carbide burrs to eat through the cylinder head material cleanly. More complex geometry can be ported using a CNC machine, using laser guidance to perfectly shape and shave the cylinder head to exact user-inputted specifications.

To properly analyse and validate the job, a head should be tested first on an air flow bench which measures the volumetric flow rate (how much air is getting in and out of the head). This will give a base figure to compare to once the head has been fully ported and polished, leading directly to a gain in horsepower.

There are many areas within the cylinder head that can be attended to:

• Exhaust ports – material can be shaved especially from the top of each exhaust port, where the highest velocity air is found exiting the cylinder. Port matching with the exhaust manifold can also be conducted, making sure there is no change in diameter between either components which could cause a restriction otherwise.

• Inlet ports – material can be shaved to relieve the port of ruts and unwanted metal from casting, but keeping a certain surface roughness so to encourage any fuel deposited on the port sides to evaporate. Changing the entire orientation of the inlet port can also be an extreme but effective form of head porting, like changing the angle of the port in relation to the runner from the inlet manifold to minimise disturbance of the fluid flow. Port matching also applies to the inlet manifold, making sure that it is a precise fit

• Valve throat pocket – possibly the most important area to have smoothed and widened, promoting the efficient movement of flow through the throat by smoothing off any edges and chamfers left by factory machining

• Valve seat – a particularly tricky job that should almost definitely be attempted only by someone with access to CNC equipment, this modification will make sure that the valves create an exact seal with the valve seat when closed, thus improving the volumetric efficiency of the engine

• Combustion chamber – polishing of the area that makes up the top of the combustion chamber (housing the spark plug) is conducive to efficient exhausting of the cylinder, with a polished finish allowing a smooth transition of the combusted air/fuel mixture out of the cylinder and into the exhaust manifold

Once power increases from other methods have been maxed-out to a point, head porting can be a great next step to producing another incremental power jump. Don’t expect huge leaps in horsepower; results obviously depend on the original state of the cylinder head and the quality of the workmanship. If you believe online forum chatter, LS1 cylinder heads can give anywhere between 10 to over 50bhp extra from a port and polish, so it is by no means a linear process.

The slight expansion of the inlet and outlet ports will slightly change the way in which your engine creates power however; torque will be sacrificed lower in the rev range due to the decrease in fluid velocity due to the new expansion of the port, but power gains will be had high in the rev range as a larger volumetric flow rate of air and fuel can makes its way into the cylinders. Couple head porting with a performance camshaft with a nice high valve lift and there can be some serious potential for higher upper rev range power output.

A word of caution before you start hacking your cylinder head apart with a drill however – this kind of modification should only be performed by someone who has past experience doing so or by handing the head into a professional shop to be machined. Over-doing head porting leaves no way back; it’ll result in a cylinder head in the bin and a costly replacement.

So don’t rely on YouTube tutorials or articles like this to go about porting and polishing a cylinder head. With an experienced touch and some well-placed grinding however, you can gain some ever-needed additional horses back under the bonnet, through what is essentially just a clean-up!

Comments

Eh, I’ll just buy stickers.

[DELETED]

bish plz

Ported the intake manifold on my Sonic a while back (its plastic so not too difficult). Dyno testing proved i got a 10hp boost at the wheels. Not bad for a free mod

#realtuning

Sexy, although port and polishing can decrease performance due to fuel condescending on the smooth inlet port surface,

How it increasing the power??? Haaa easy!

MONEY$$$$$$

Ha! Welcome to rotaries, where porting can double horsepower. (And porting does the same as camming)

My brain crashed guys

So this process is only removing the extra bits that are produced by the molding process right by polishing it with a grinder right?

Hot rodders have been doing this for ages

Pagination