#TechTip: Compression Ratios

“Compression ratio” is a term thrown around a lot when you’re talking about engine specs, but what does it really mean?

“Compression ratio” is a term thrown around a lot when you’re talking about engine specs, but what does it really mean?

For the most part, when people are talking about an engine’s compression ratio, they’re talking about what’s called the static compression ratio, which is much simpler to calculate than the dynamic compression ratio.

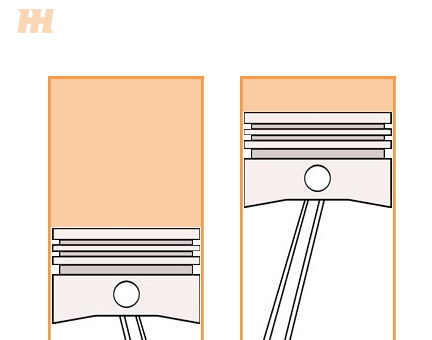

To put it simply, the static compression ratio (usually just referred to as the compression ratio) is the ratio of the maximum volume to the minimum volume in a cylinder as the piston moves (the volume when the piston is all the way down compared to when it’s all the way up).

What does a compression ratio mean?

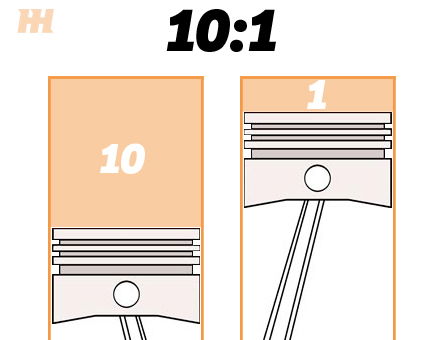

CRs are basically telling you how much the air/fuel mixture in the cylinder are being compressed before the spark plug ignites it. So if you have 10 units of volume when the cylinder is at the bottom of its stroke, and 1 unit when the cylinder is at the top of its stroke, the compression would be referred to as being 10:1. For naturally aspirated motors, higher compression ratios tend to mean higher power figures.

What are the consequences of higher compression ratios?

The higher the compression ratio, the more likely you are to experience pre-detonation (also known as pinging). Pre-detonation occurs when an air fuel mixture ignites due to excessive pressure (rather than because of the spark). This makes sense, as more compression = more pressure = more likelihood of an explosion. To combat pinging, higher octane fuels are often used. The higher the octane fuel, the more resistant to pre-detonation it is.

It is also important to note that heat plays a role in pinging. The hotter the temperature, the more likely a detonation is to occur. Because aluminium is better at dissipating heat than cast iron, engines with aluminium heads can often run higher compression ratios than their cast iron counterparts without experiencing pinging.

Why would you want a lower compression ratio?

Lower compression ratios come in handy for engines which use forced induction or engines that want to take advantage of a lower octane fuel . For example, you may find that very high horsepower builds that use turbochargers or superchargers actually have a very low static compression ratio. Lower compression was largely used in 70s and 80s American cars as a result of emission reduction attempts.

How to change compression ratios:

Compression ratios can be changed by changing engine components such as pistons and heads. When pistons have more relief (or dish), they result in lower compression ratios than pistons which are flat or domed, which usually feature increased compression ratios.

Heads are another popular option for changing compression ratios. Heads that feature smaller combustion chambers will increase compression ratios, while heads with larger chambers result in lower compression.

Comments

Is pre-detonation the correct term? Detonation means unwanted ignition in the combustion chamber, and since there isn’t any “main” detonation (I think) , pre-detonation doesn’t really make any sense.

no discussion about compression ratios is complete without mentioning the Carnot cycle. It’s a thermodynamic principle that sets the upper limit for the efficiency of an engine (or the amount of energy you can extract from fuel). Basically the greater the differences in pressure the more power you can make.

9 layer head gasket got my cp down

Higher compression ratios give more power in N/A motors though. Another important thing to point out on the subject.

“What are the consequences of higher compression ratios?” You blow the welds on your… exhaust manifold? bruh

We need more posts like this! thanks!

Why do you need to lower the CR when installing forced induction ? I heard that before but it was never explained to me

Pagination